Lithium battery spot welding machine

Follow me on:

Spot Welding Machine for Lithium Battery - New Energy Solution

Topower's spot welding machine is for cylindrical cell assembly, welding with fast programming and good consistency to ensure production quality. Get expert advice today.

Exalting Precision: A Profound Expedition into spot welding machine

Inauguration

spot welding machine, a linchpin in the tapestry of contemporary manufacturing, has traversed an intricate trajectory from its historical genesis to its indispensible role in present-day production. This discourse plunges into the intricacies of spot welding machine, elucidating its technological acumen, diverse applications across sectors, and the pivotal role it assumes in sculpting precision welding.

I. Comprehending spot welding machine: A Technological Enigma

At the vanguard of precision welding stands spot welding machine, orchestrating a process involving the astute application of heat and pressure to create localized welds. These apparatuses embody an array of meticulously crafted components, each calibrated for optimal performance, with assorted types tailored to specific welding imperatives.

II. Applications Across Industries: Revelations of Spot Welding's Versatility

The versatility of spot welding machine becomes palpable across multifarious industries. In the realm of automotive manufacturing, these apparatuses prove indispensable for body assembly, safeguarding structural integrity. The electronics domain benefits from the finesse of small-scale welding for intricate components, while the aerospace sector leans on spot welding for the fusion of lightweight materials, amplifying overall efficiency.

III. Types of Spot Welds: Immersion into Precision Welding Techniques

Spot welding encapsulates diverse techniques, each finely tuned to specific applications. Resistance Spot Welding (RSW) emerges as the epitome in manufacturing, vouchsafing robust welds. Capacitor Discharge Spot Welding (CDW) emerges as ideal for delicate materials, while Pulsed Laser Spot Welding bequeaths high-precision welds, particularly in challenging scenarios.

IV. Innovations and Technological Strides in spot welding machine

The landscape of spot welding machine is in perpetual flux. The infusion of automation and the amalgamation of robotics accentuate operational efficiency, while advanced control systems contribute to the attainment of optimal weld quality. The infusion of artificial intelligence facilitates predictive maintenance, ensuring a seamless continuum of production.

V. Key Considerations in Opting for the Appropriate spot welding machine

The sagacious selection of spot welding machine involves scrupulous contemplation of factors such as material compatibility, thickness, production volume, speed requisites, and energy efficiency. These facets collectively contribute to the efficacy of the apparatus in a specific manufacturing milieu.

VI. Comparative Analysis: Scrutinizing Divergent Spot Welding Technologies

A dissection of the performance and precision of divergent spot welding technologies unfolds. Resistance Spot Welding undergoes juxtaposition against Capacitor Discharge and Pulsed Laser Spot Welding, proffering insights into their respective forte and limitations. Additionally, a cost-benefit analysis buttresses decision-making for sundry spot welding applications.

VII. Case Studies: Poring Over Successful Deployments of spot welding machine

Real-world case studies cast a spotlight on successful deployments of spot welding machine. In the automotive sector, these apparatuses augment production efficiency, while in electronics manufacturing, they achieve microscale precision. Aerospace applications underscore the pivotal role spot welding plays in ensuring structural integrity.

VIII. Futuristic Trends in Spot Welding Technology

Anticipating future trends in spot welding technology unveils ongoing advancements. Innovations in materials, the integration of Industry 4.0 principles, and the role of spot welding in sustainable manufacturing practices emerge as pivotal facets shaping the trajectory of these apparatuses.

IX. Challenges and Panaceas in Spot Welding Technology

Spot welding technology contends with challenges such as heat-affected zones, consistency in large-scale production, and environmental ramifications. This section unfurls panaceas and strategies to assuage these challenges, ensuring the continued efficacy of spot welding machine.

X. Conclusion: Navigating the Future of Precision Welding with spot welding machine

In conclusion, this discourse encapsulates the odyssey of spot welding machine, accentuating its evolution, diverse applications, and ongoing technological strides. spot welding machine emerges as a pivotal instrument in the repertoire of modern manufacturing, guiding the industry toward a future defined by precision, efficiency, and sustainability.

Lithium Battery Spot Welding Machine: Precision and Efficiency in Battery Manufacturing

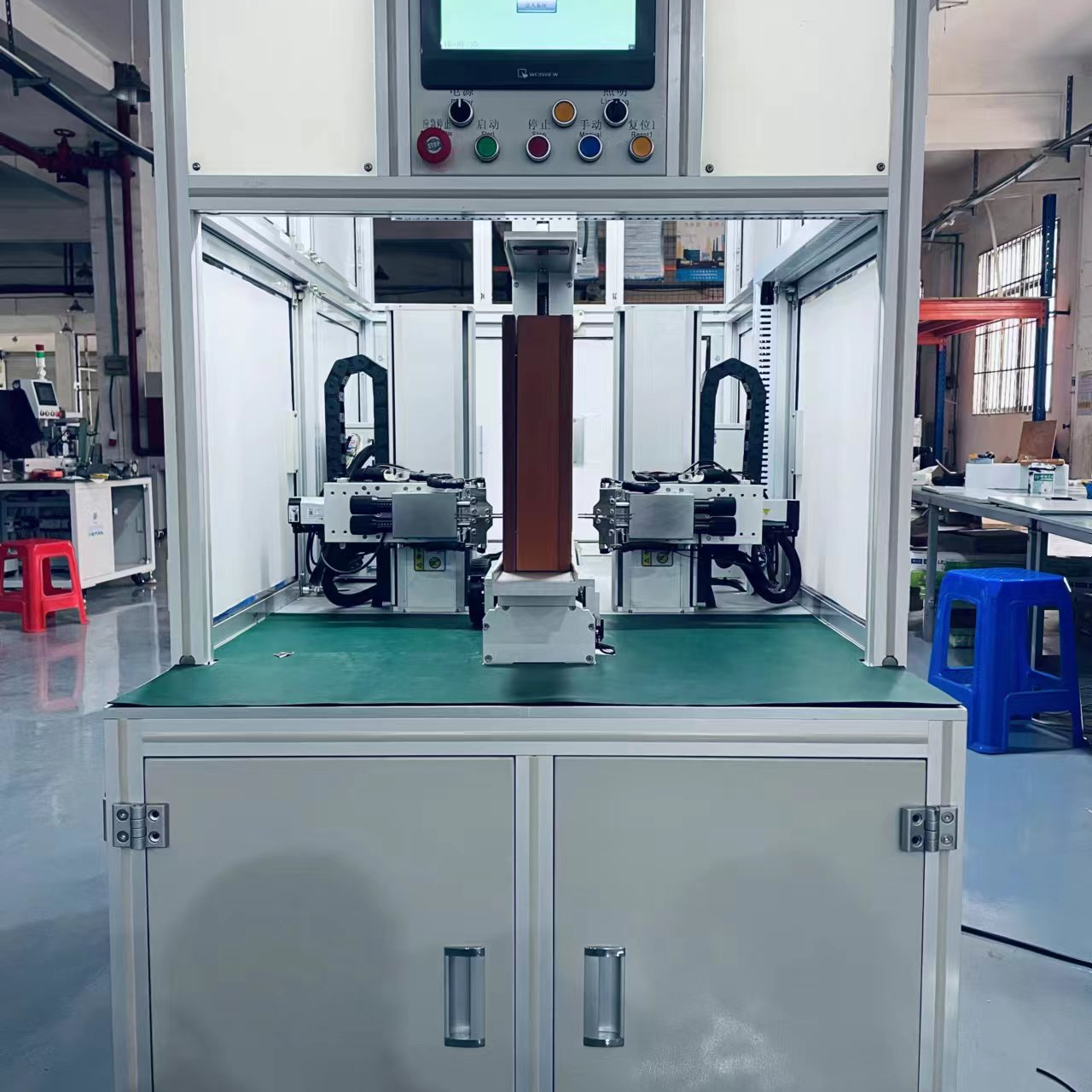

The Lithium Battery Spot Welding Machine is a cutting-edge piece of equipment designed for the precise and efficient welding of cylindrical lithium-ion cells. It plays a critical role in the assembly process of modern battery packs, ensuring the structural integrity and electrical performance of cylindrical cells.

Operational Mechanics of the Spot Welding Machine

This state-of-the-art machine employs a blend of automated technology, precision engineering, and intelligent software to deliver consistent and reliable welding results. The workflow is streamlined through the following stages:

1. Cell Positioning: The cylindrical cells are fed into the machine where they are precisely aligned for welding.

2. Welding Execution: The machine uses a high-precision welding head that can rotate 180° to ensure optimal contact and uniformity in the welding process.

3. Quality Assurance: An integrated monitoring system provides real-time feedback on the welding quality, including automatic compensation for wear and tear on the welding needle.

4. Alarm and Feedback: The system alerts operators to any poor welding instances, facilitating immediate corrective action.

5. Data Recording: Each welding session is recorded, allowing for traceability and quality control analysis.

Advantages for Battery Manufacturers

Incorporating the Lithium Battery Spot Welding Machine into your production workflow offers several advantages:

- Efficiency: With a spot welding speed of 0.8-1 second per piece, the machine can process 4000-4500 pieces per hour, enhancing production efficiency.

- Consistency: The machine ensures welding consistency, reducing the likelihood of false welding and improving the overall quality of the battery packs.

- Automation: Automatic feedback compensation for welding current and a motion controller reduce manual intervention, leading to fewer errors and increased productivity.

- Versatility: The machine can store up to 99 groups of files, allowing for a wide range of welding parameters to be used for different cell types.

Customization and Adaptability

The machine is not limited to standard applications; its design allows for customization to fit various production requirements. It can be adapted to handle different cylindrical cell sizes and welding specifications, providing a flexible solution for diverse battery manufacturing needs.

User-Friendly Interface and Integration

Designed with user convenience in mind, the Lithium Battery Spot Welding Machine features a simple operation interface and fast programming capabilities. It can be easily integrated into existing battery production lines, ensuring minimal disruption and swift adoption.

After-Sales Support and Services

We stand by our product with a comprehensive after-sales service package. This includes installation support, operator training, and ongoing technical assistance to ensure the machine performs at its best. Our commitment to customer success is backed by remote support for rapid issue resolution.

To discover how the Lithium Battery Spot Welding Machine can revolutionize your cylindrical cell battery production, reach out to us today. Experience the benefits of precision welding, enhanced quality, and streamlined operations that give you the edge in the competitive battery industry.

Application: This machine is applied to cylindrical cell double-side welding. Functions are: the welding head can rotate by 180°, the welding is consistent, the welding needle is not sticky, the welding needle wear is automatically compensated, the poor welding alarm, real-time monitoring, recording, welding current automatic feedback compensation, motion controller, display and non-array battery pack, simple peration and fast programming, current welding monitoring and alarm, solving the phenomenon of false welding, support breakpoint start, automatic and manual mode conversion, the brief information is as follows:

Parameters:

- Power supply: three-phase 380V±10%/50Hz±10%, power <2000W.

- Y-axis travel: 560MM, Z-axis travel: 240MM.

- Spot welding speed: 0.8-1S/piece; 4000-4500 pieces/h.

- Number of groups of files that can be stored: 99 groups

- Transmission mode: servo motor + imported precision linear guide

- Maximum number of batteries: 200pcs (18650 cells)

- Nickel sheet thickness: 0.5mm or less